Most rubber feet are made of rubber and other materials (metal, fiber, plastic, etc.) by bonding and vulcanization. They are usually under external force when used. When the external force exceeds a certain limit, the bonding part will be destroyed. The use of rubber feets is lost, which is called “joint breakage.” In fact, this naming is not very accurate, because some debonding does not occur at the bonding interface, even regardless of the bonding material used. The damage of the rubber feets bonded to other materials can be summarized as the following four categories.

(1) Cohesive failure of the adherend

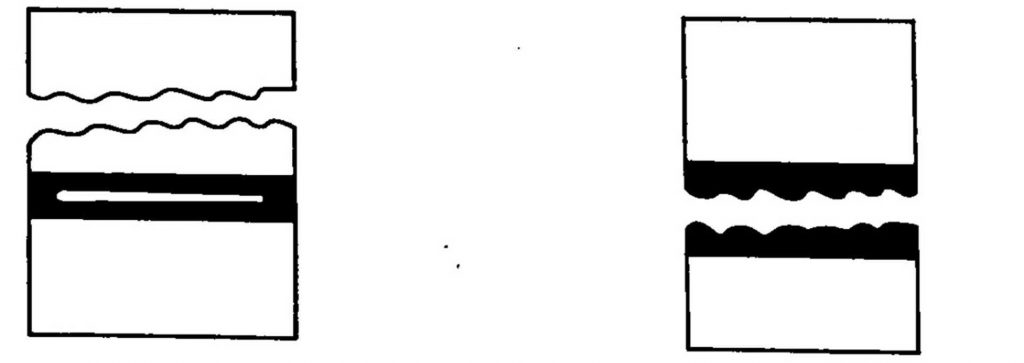

The fracture surface appears on the material to be bonded, as shown in Figure 4.10. This reflects that the adhesive strength of the adhesive exceeds the strength of the material to be bonded, or the strength of the adhesive material is lower than the adhesive strength of the adhesive, but this situation is relatively rare and should not occur unless the structure of ruber feets There are problems such as the presence of holes or holes.

(2) Cohesive failure of adhesive

The interface adhesion has exceeded the material strength of the adhesive. It shows that the bonding process is perfect and belongs to the ideal bonding state.

(3) The adhesive interface is disconnected

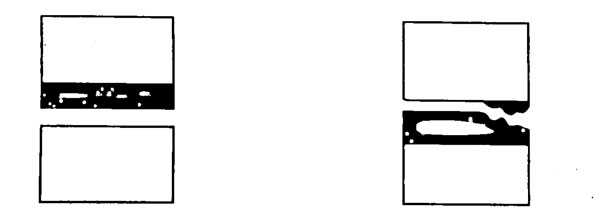

Debonding occurs at the bonding interface, and generally the fracture surface is flat. If the bonding strength is up to standard, it is still normal.

(4) Mixed destruction

This situation is rare, and the debonded portion exists both at the interface between the adhesive and the adherend, and also partially inside the adhesive. The cause is that the texture of the adhesive is not uniform, resulting in different levels of adhesion, and there are two types of damage coexisting at the same time.

Type of rubber feets bonded to other materials,(1)and (2)

Type of rubber feets bonded to other materials,(3)and (4)

According to the analysis of the above four cases, the (1) and (2) kinds of reflection glue and bonding processes are ideal, and there is no missing. In particular, the second type (2) excludes the problem that the material of the material to be adhered is poor. The third (3) species is a normal condition. Item (4) is attributed to improper surface treatment.

The above focuses on the common causes of damage to the bond head from a material and process perspective. However, in fact, the external conditions can not be ignored, especially the test conditions, such as the tensile speed of the tensile machine, the ambient temperature of the test chamber. Sometimes cohesive failure occurs during slow stretching, and the adhesive interface is disengaged during rapid stretching.

Another common influencing factor in external conditions is the presence of internal stress in the joint, which often reduces the bond strength data and affects the authenticity of the test data. The internal stress often encountered is divided into two types: contraction stress and thermal stress. In order to avoid the resulting interference, it is generally required to use a curing temperature as low as possible (preferably room temperature) and a low elongation, high elongation adhesive.