Thermal expansion and contraction are the objective laws of all substances in nature, and rubber is no exception. However, it must be considered that most rubber feet are not pure rubber, but various additives have been added, and the added ingredients will affect the shrinkage of rubber feet to varying degrees. That is to say, considering the shrinkage rate of rubber, it is impossible to ignore the influence of the composition of the formulation.

The importance of mastering the rubber shrinkage is twofold: first, the rubber feets are within the allowable tolerances; second, based on the shrinkage, the machining allowance at the time of mold opening is determined to determine the mold size. Generally, the shrinkage rate of rubber feet after vulcanization is in the range of 1% to 3%. The main factors affecting the shrinkage rate are roughly as follows.

- The shrinkage rate of different types of rubber (referred to as unfilled) is different, such as styrene-butadiene rubber>natural rubber>chloroprene, which will inevitably affect the shrinkage of the rubber compound.

- The amount of filler also contributes to the shrinkage because the linear expansion coefficient of the filler differs from the expansion coefficient of the rubber by two orders of magnitude, and is of the same order of magnitude as the mold material (steel). Therefore, as the filling amount increases, the shrinkage rate also decreases.

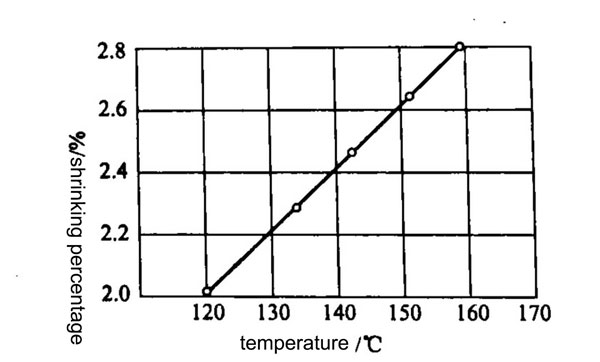

- Vulcanization temperature practice shows that as the vulcanization temperature increases, the shrinkage rate increases, and the reason is related to the accelerated volatilization of volatiles in the rubber composition. The correlation obtained with natural rubber as an example is sufficient to illustrate the problem.

A Therefore, increasing the filling amount and lowering the vulcanization temperature all contribute to a reduction in shrinkage. The calculation of shrinkage rate is based on practical applications, and there are two calculation methods to choose from.

1 Based on the dimensions and mold size of the vulcanized rubber feet measured at room temperature

Calculate the shrinkage rate.

2 Based on the difference between the temperature difference and the coefficient of linear expansion, the sum of the volume fraction of the rubber and the volume fraction of the acetone extract.

The first calculation method is applicable to both the mold and the product sample, and is suitable for the production unit; the second method is applicable to the rubber feet design drawings and the rubber compound formula, but the mold is still in processing. Case. In order to reduce the workload of mold modification and rework, the second formula can be used to provide reference data for mold processing.